As laser technology remains to development, so does the relevance of the crystals utilized to power them. Holmium-doped Yttrium Light Weight Aluminum Garnet (Ho: YAG) crystals are currently at the center of this development, particularly for their exceptional utility in mid-infrared lasers. Let’s explore the remarkable world of Ho: YAG crystals.

Ho: YAG crystals, doped with holmium ions (Ho3+), are differentiated for their unique characteristics:

Among the specifying characteristics of Ho: YAG crystals is their one-of-a-kind spectral homes.

Ho: YAG lasers operate at a main wavelength of 2.1 µm, located in the mid-infrared region. This wavelength is absorbed by water and also organic cells, allowing precise and also regulated interactions in clinical procedures.

Ho: YAG crystals feature wide absorption bands in the 600-900 nm and also 1800-2100 nm areas. This enables them to properly soak up power from different pump resources, consisting of flash lights as well as diode lasers.

The thermal and mechanical properties of Ho: YAG crystals add significantly to their performance in laser systems.

Ho: YAG crystals have high thermal conductivity, ensuring they can endure the heat generated throughout laser procedure. This residential property assists to maintain the architectural honesty of the crystal and also prevent damage during high-power result.

Ho: YAG crystals have a high laser damages threshold. This suggests they can manage intense laser light without damages, which is particularly crucial for high-power laser applications.

The chemical homes of Ho: YAG crystals likewise play a significant role in their effectiveness and also toughness.

Ho: YAG crystals show high chemical security. They are resistant to many acids and antacid, guaranteeing their long life even under challenging problems.

With a Mohs firmness of around 8.5, Ho: YAG crystals are very immune to scrapes as well as mechanical wear. This firmness contributes to their longevity and also lengthy service life.

Production Ho: YAG (Holmium-doped Yttrium Aluminum Garnet) crystals is an elaborate and thorough procedure. It requires crystal growth, followed by post-growth handling, to prepare the crystals for their duty in laser modern technology.

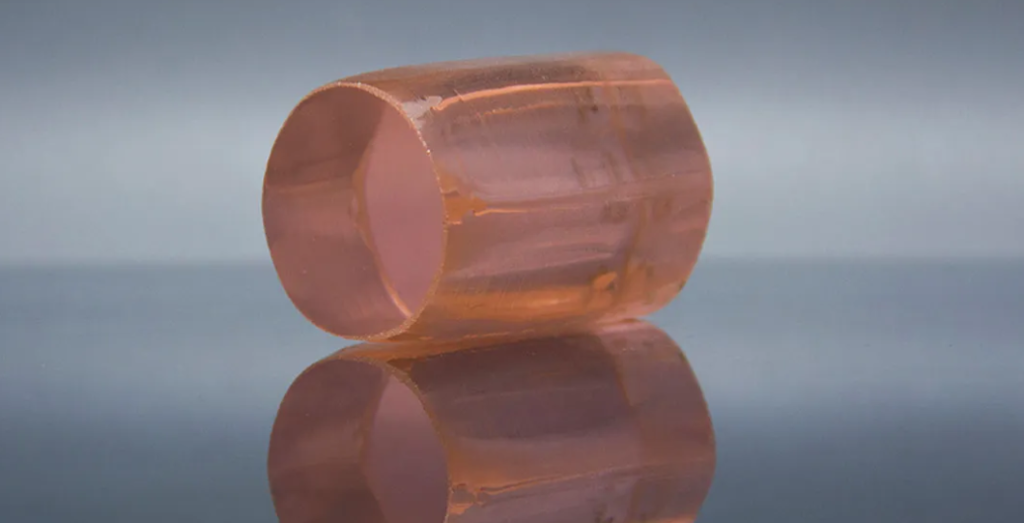

The production procedure of Ho: YAG crystals starts with crystal growth, specifically making use of the Czochralski method.

The Czochralski method is a well-established process for growing single-crystal round boules. The procedure begins with preparing a high-purity mix of yttrium, light weight aluminum, as well as holmium oxides. This mix is positioned in a crucible as well as warmed up until it melts.

A seed crystal is dipped into the liquified blend. As the seed crystal is slowly taken out, the molten material solidifies around it, creating a large, single-crystal cylinder of Ho: YAG.

Throughout the crystal growth procedure, numerous criteria need to be very closely kept track of to ensure a top quality crystal. These consist of the pulling price, rotation rate, and the temperature of the melt. Also minor discrepancies can substantially affect the crystal’s top quality.

As soon as the crystal growth is complete, the resulting round boule undergoes a number of post-growth handling actions.

Initially, the crystal is oriented along specific crystallographic axes using X-ray diffraction. It is after that cut into the wanted size and shape, normally into rectangular slabs for laser applications.

After cutting, the surfaces of the crystal slabs are brightened to optical quality. This action is crucial as any surface area defects or roughness can create scattering of the laser light, lowering the performance of the laser.

The last action is to apply anti-reflective or high-reflective coatings as called for. The option of finish depends on the particular application of the laser.

The performance of Holmium-doped Yttrium Aluminum Garnet (Ho: YAG) laser crystals in mid-infrared lasers is exceptional. They exhibit remarkable residential or commercial properties that establish them apart as well as make them the crystal of choice for a wide array of applications.

The high quantum performance of Ho: YAG crystals contributes to their premium efficiency. Their wide absorption bands in the 600-900 nm and also 1800-2100 nm regions make them efficient in effectively taking in power from various pump resources, causing reliable energy conversion as well as high output power.

Ho: YAG crystals are known for their exceptional beam of light top quality. The mono-crystalline structure of the Ho: YAG crystal makes sure marginal distortion to the laser beam of light, enabling a top quality, constant output. This is specifically vital in applications requiring high accuracy, such as operations and also material processing.

The thermal homes of Ho: YAG crystals, such as their high thermal conductivity as well as reduced thermal expansion coefficient, contribute to steady laser operation. They can effectively dissipate the warmth created during laser procedure, stopping thermal lensing and also ensuring consistent outcome over extended periods.

The versatile nature of Ho: YAG crystals is another aspect adding to their outstanding performance. Their unique discharge wavelength at 2.1 µm, in the mid-infrared area, opens up a plethora of applications. This wavelength coincides with high absorption in water and organic tissues, making Ho: YAG lasers specifically efficient in medical procedures.

Ho: YAG crystals are recognized for their toughness and longevity. Their high damage limit as well as exceptional chemical stability ensure they stay functional as well as reliable even under rigorous operating problems. This makes them a cost-effective choice for various applications, adding to their general performance.

Mid-infrared lasers, those that run in the wavelength variety of 2-5 µm, locate considerable applications in a host of fields. An essential part of these lasers, particularly in the shorter wavelength area of the spectrum, are the Holmium-doped Yttrium Aluminum Garnet (Ho: YAG) crystals. With their emission optimal at 2.1 µm, Ho: YAG crystals have promoted technology and also broadened perspectives in numerous domain names.

In healthcare, the implications of Ho: YAG lasers have been revolutionary, reshaping the concept of surgery as well as causing a standard shift in the direction of minimally intrusive treatments.

Ho: YAG lasers have discovered considerable application in ophthalmology, especially in treatments like posterior capsulotomy and also vitreolysis. The lasers’ high absorption in eye tissues allows the accurate reducing required in these treatments, decreasing any possible damages to surrounding tissues.

Using Ho: YAG lasers in urology has actually been transformative, specifically in the treatment of kidney rocks. The precision and control provided by Ho: YAG lasers have made lithotripsy, the procedure of breaking down kidney rocks, an extra effective and also less excruciating procedure.

Ho: YAG lasers have actually made oral procedures such as dental caries prep work, periodontal surgery, and origin canal treatments considerably more comfortable and also much less distressing for clients. By facilitating quicker recovery and lowering post-operative discomfort, they have improved individual results and fulfillment.

Past health care, Ho: YAG lasers have actually made substantial strides in numerous industrial applications. Their ability to supply high-powered, focused energy makes them an important tool for accuracy product handling.

In industries where precision is vital, like the electronics and also aerospace industries, Ho: YAG lasers have come to be necessary. They are made use of for elaborate tasks such as reducing as well as drilling, particularly in materials like steels, porcelains, as well as polymers. The lasers’ high precision as well as very little heat affected area cause cleaner cuts as well as openings, minimizing the requirement for post-processing.

Ho: YAG lasers are likewise commonly used for laser noting, where they engrave high-resolution markings on numerous products. These markings are vital for identification, traceability, as well as quality assurance in manufacturing procedures.

Ho: YAG lasers likewise play a crucial duty in clinical research study. They contribute in establishing new technologies as well as understanding our globe at a deeper degree.

In spectroscopy, Ho: YAG lasers are utilized to recognize as well as evaluate various materials. This is particularly appropriate in environmental monitoring, where tracking toxin levels is critical. By utilizing the unique absorption features of molecules in the mid-IR array, Ho: YAG lasers make it possible for the precise detection and tracking of these pollutants.

Ho: YAG lasers are also adding to the expedition of quantum physics. Their precise control over light bits or photons is assisting scientists acquire much deeper understandings right into the quantum realm.

With every passing day, the applications of Ho: YAG crystals in mid-infrared lasers remain to increase and also progress. As we grow our understanding of these crystals and also their communication with light, brand-new applications will certainly remain to emerge, better underscoring the enormous capacity of Ho: YAG crystals in transforming the globe around us.

To conclude, Ho: YAG crystals are the beating heart of mid-infrared lasers. Their special homes, combined with their compatibility with numerous applications, make them one of the most substantial innovations in laser innovation. The future of these crystals guarantees additionally enhancements in healthcare, market, as well as beyond.

What is a Ho: YAG Laser Crystal?

Ho: YAG laser crystals are artificial crystals doped with holmium ions (Ho3+), mostly used in mid-infrared lasers because of their absorption and exhaust of light in this spectrum.

Exactly how are Ho: YAG crystals made?

Ho: YAG crystals are grown using the Czochralski method, which involves thawing a high-purity blend of yttrium, aluminum, as well as holmium oxides and gradually drawing a seed crystal out to create a single-crystal cyndrical tube of Ho: YAG.

Why are Ho: YAG crystals made use of in mid-infrared lasers?

Ho: YAG crystals’ discharge wavelength of 2.1 µm straightens with an extremely absorptive water and also biological tissue band, making them optimal for medical applications, among others. Their high thermal conductivity additionally ensures stability in high power operations.

What are the applications of Ho: YAG lasers?

Ho: YAG lasers have varied applications, particularly in non-invasive clinical procedures and also product processing in numerous sectors. Future study could expand their applications further.

What does the future hold for Ho: YAG crystals?

The future of Ho: YAG crystals is appealing, with possible applications in quantum computing as well as telecommunications. By improving the crystal growth as well as doping processes, their efficiency is likely to boost.